It will be tough to post sales increases this year, so focus on opportunities that you can easily control.

Operations by Dan Bolger

“To improve is to change; to be perfect is to change often” is a Sir Winston Churchill quote that strikes home in these difficult times. That quote, and the use of Managing By Walking Around techniques (described in the 1982 book “In Search of Excellence” by Tom Peters and Robert Waterman) are the driving principles that need to be used by every furniture retailer in these tough times. In recent years Lean process has contributed another dimension to overall best practices strategy.

In simplest terms, applying Lean principles to furniture warehouse and delivery provides a framework to eliminate waste every step of the way with the ultimate goal of achieving a perfect delivery.

For most furniture retailers it is virtually impossible to increase sales this year, so you need to focus on items you do control. This article is focused on opportunities that you identify using your eyes and ears through “Managing By Walking Around” and the use of common sense. If you have broad management responsibilities, rearrange your schedule to spend time in warehouse and delivery operations over a three-week period. Your entire first day should be spent in operations. Based on what you see while walking around, you will probably want to visit the warehouse on subsequent days to observe operations needing improvement and develop action plans to address these issues.

Observe Delivery

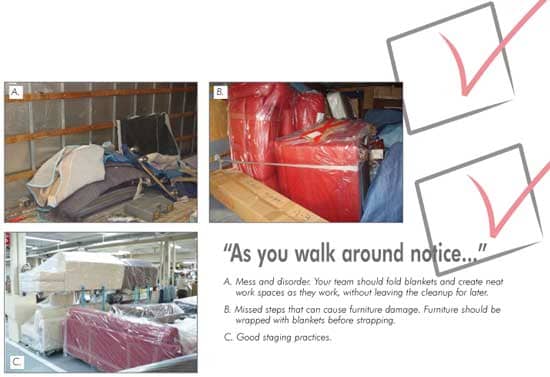

- Was the workplace left clean and neat the previous night for the start of the new day?

- Is the entire staff at their work stations ready to start work on time or, do people sit around drinking coffee and chatting?

- Does the warehouse manager have the day’s work planned so there is productive work that can be started immediately. Conversely, are on time workers killing time while a manager figures out what has to be done?

- Assuming that your company loads trucks in the morning, are returns already properly identified, unloaded, accounted for and waiting in your returns area?

- Are there procedures in place to help your employees understand why the goods came back?

- Are there mysteries to be solved regarding previous deliveries or

non-deliveries?

- Are the trucks swept out, and are blankets and tools already loaded on the trucks?

- Are all the goods properly prepped and ready to go?

- Are there any defects to be fixed before loading?

- Is the dock well organized so the delivery team can load the truck in a timely manner, or are there delays while they hunt for missing parts or units?

- Is furniture being dragged on concrete or are dollies and/or hand trucks used to properly handle furniture?

- Is everything blanketed in the truck?

- Is the light side of the blanket always toward the product and dark side out? Are all furniture surfaces protected from damage?

- Are ties properly used to prevent products from shifting?

- As each delivery team prepares to leave, pay attention to their appearance. Do they properly represent your business image, whether in uniform or personal work clothes?

Observe Receiving

- Are all the support documents available for easy reconciliation?

- What can be done to reduce the time between receiving and delivery?

- Can the distance traveled between receiving, warehousing, prep and delivery be shortened?

- Walk the warehouse and observe put-away and stock pulling. Is everyone hustling?

- What stock is dusty or possibly damaged which indicates lack of inventory control?

- Are cycle counting programs in evidence?

Observe Prep

- Can unpackaging and basic prep be done by less skilled workers?

- Are the most skilled workers doing highly productive work?

- Is merchandise movement efficient?

- How is the trash handled?

- Observe the staging for each truck bay.

Visit The Shop

- What is the level of professionalism in every aspect?

Visit The Office

- Listen to office communications and observe the functions.

- How do the staff members work together to achieve

overall customer service goals?

Throughout this grand tour, consider whether you would be pleased to have your customers walk through with you, including the break areas and restrooms. That’s an acid test.

As you move from area to area, speak with all the people who contribute to operations. People who actually do the work are frequently aware of, and glad to tell you what needs to be done. Sometimes though, management never asks or is not listening.

Your notes will provide an internal assessment of strengths and weaknesses. They will help you focus on improvements achievable with your internal staff and help you determine areas in which you may need to hire outside consultants to supplement your in house expertise. You may also want to reference previous FURNITURE WORLD Magazine articles (posted to the Operations Article Archives on the furninfo.com website) that provide specific recommendations for receiving, hiring and compensation.

Daniel Bolger P.E. provides operations consulting services to clients throughout North America. FURNITURE WORLD Magazine readers can contact him at bolger@furninfo.com. For more information on this or other transportation, logistics and furniture warehousing topics, go to www.furninfo.com to read all of Dan’s articles.