Any business model functions in a chain of activities. Each job function or process is a link in a chain playing a critical role in adding value to the previous function. It, in turn, passes on value to the next function. If there is a weak link in your chain of operations, it will eventually break, causing your operation and customer experience to suffer.

Let’s use the purchase process as an example. Suppose a customer wishes to special-order a table. She reviews all the details with her salesperson who writes up a sales order. The sales order is given to the purchasing manager who keys in the PO and specifies a flat black finish. The merchandise arrives, the delivery is scheduled and delivered. When the customer sees her table, she is dismayed. She wanted gloss black finish and asks for a refund.

This is just one example of hundreds of breaks that occur in the chain of operations. If this business had a stronger link between the salesperson and the purchasing process, this kind of problem could have been avoided.

The diagram below represents various links in the chain of a retail furniture store operation. Each role must be completed perfectly before proceeding to the next link in the chain.

Critical Links in the Chain of Operations

Marketing: The first link in your business chain is obvious. It is the role of marketing. There is no business without customers. Whatever your media and networking combination, its purpose is to obtain relevant sales leads. If your product is high-end luxury contemporary merchandise for example, you probably don’t want high school kids visiting you. You would much prefer a high income, style conscious customer, right? So, that’s where your marketing focus should be. Know your customer and target your efforts directly to that audience. Businesses with a strong first link will get more selling opportunities. Businesses with a broken first link don’t produce enough leads and have a difficult time growing their operations.

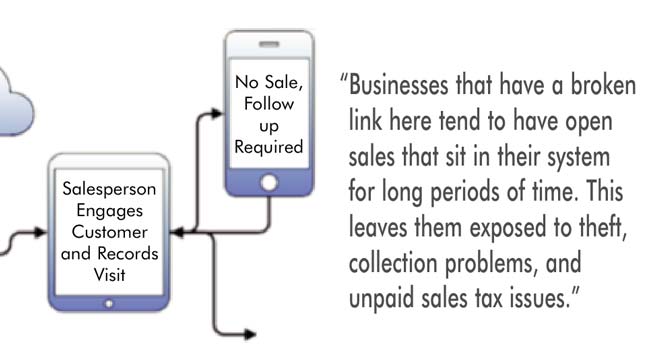

Initial Customer Visit & Salesperson Engagement: Serving your customer professionally is the goal of engagement. This is where a good CRM (customer relations management) system can help. Salespeople work with customers to help them discover and solve purchasing challenges. A certain percentage of customers do not buy on their initial visit, however. That’s why capturing customer visit data is important. This can be done through a variety of methods ranging from VIP draws to writing up quotes. The next best thing to a buying customer is one who leaves after giving you their contact information. Which leads to the next link…

Follow Up with CRM: The only purpose of a lead is to follow up on it. If there is no system to follow-up on leads, most will die a quick death. CRM encourages this follow-up. Customers who give you their information deserve to be contacted. To increase your chance of getting through, contact them with a relevant communication in a media that they prefer. If they signed up for your VIP list, send them a monthly email with a discount or drawing opportunity. If they got a quote, call and email them a product update with information to help them make their decision. You will find that the top salespeople in the world have a talent for follow-up. Use a CRM system to help your average salespeople become great salespeople. These systems generate information so the follow up can be executed and managed. Customers are not forgotten.

The Sale: When the sale is made, it is critical to get it entered in a timely and 100% accurate fashion. Delays in sale entry cause inventory counts to be off, resulting in all sorts of potential problems. The sale must be entered with the correct quantities, location, amounts, tax, items, salesperson, delivery or pick up method, addresses, payment terms, and special instructions.

iPad and PC tablets are great ways to get the sale entered in a timely and professional manner.

Just telling your people to do this does not always make it happen. Every link in the chain must be managed. One purpose of management is to inspect what you expect. Without inspecting work, there will be errors and customers will suffer. At the end of each day’s business, review all sales for the day.

Daily Cash Receipts: Perfect control of daily cash in your system is required. Forget manual day sheets unless you are committed to being a pen and paper operation. Every retail software system includes a report to review daily cash receipts. At the end of each day or following morning, run a cash report for the cash, checks, credit cards, and finance payments received into your system. Compare it against the physical cash, checks, and credit card totals collected. If there is a discrepancy, either someone made a mistake entering a receipt, the money never came in, or it is somewhere else. Rectify all issues immediately. This process should take under 20 minutes per day for even large operations.

If Merchandise Is Taken From Stock

When merchandise is sold, it is either taken from stock or special ordered. If taken against stock, the correct location of the items in inventory must be attached in the system. For example, if you have one item on the floor and one of the same items in your warehouse, the entry person needs to make sure the customer’s sale is assigned appropriately.

After choosing the right item location, the date of the pick up or delivery should be set in the system. If unknown, it should be determined ASAP or Not Set.

Take-With: In the situation where customers take products with them, a receipt should be generated for them to sign upon taking possession of the goods. As a rule of thumb whenever merchandise comes into a building or leaves a building there needs to be a receipt. During the sale entry of a take-with item, the sale can be billed or finalized at that time. The merchandise moves out of the books and the customer’s account is invoiced.

Pick-Up: On pick-up where a customer comes in at a later time, receipt of the product is required. The customer signs for the merchandise. Payments are accepted where necessary. The signed receipt is retained and forwarded to your office by the end of the day.

Delivery: If merchandise is in stock and the customer wishes delivery, the sale should be dated appropriately in the system. This date acts as a communication tool between various departments and your customer. It allows the salesperson to know when the customer expects the merchandise; the warehouse to know when to get the inventory ready; the office to know when the sale is expected to be invoiced.

Furniture Stock Needs To Be Ordered

Special Order Purchasing For Customers: I am a believer in point-of-sale entry. That means that the sale is entered in front of the customer at the time of the sale. Operations that can’t do this have to rely on interpretation of various handwritings at some point after the sale. If a customer requires a special order, it makes sense to have them agree to the specific details by involving them in the process at the point of sale as well. After sales are entered each day, purchase orders can be generated for sales that are not assigned against in-stock merchandise. The PO’s should be double checked by salespeople, the purchasing staff, or both before being placed. They should include the customer’s name and sale number.

Stock PO’s: The other type of purchase order is for stock. Like customer PO’s, stock PO’s should be done in your system at the time of ordering. Never hand write them or place orders verbally with a vendor representative. One of the biggest breaks in the chain of operations occurs here. Someone tells the rep to order some merchandise and the PO never gets entered. When the merchandise arrives, the warehouse has no idea what to do with it. Enter the PO in real time and this won’t happen to you.

The PO number is your master merchandise tracking number and all orders must be placed with a system PO number. Require that vendors use this same reference number.

Purchase Follow-Up: PO’s should be acknowledged. The estimated arrival dates should be updated. The costs should be adjusted. The accuracy of the order should be reviewed. Unless an order is transmitted via EDI or through a vendor’s system online, there is a chance of error on entry. The acknowledgement gives you time to correct errors. In integrated systems, this process also updates the salespeople’s CRM info so that you can communicate with customers regarding order status. It also communicates the expected arrival times for new stock.

Receiving Preparation: Insist that all vendors schedule incoming freight. Get them to send a packing list via email prior to the freight’s arrival. This enables your warehouse crew to be ready for the truckload. The appropriate staff can be scheduled. Bar code labels can be preprinted and organized. The dock can be cleared. It will not get jammed by multiple unexpected containers arriving at the same time. You will be ready.

Receiving: One person should direct the receiving crew. This person needs to have all the bar code labels organized on a large receiving table by the dock. After a crew member moves the merchandise from the truck, he needs to stop so that the receiving director can scan the label and stick it on the product. If the warehouse has a wireless system the quantities in the system will be updated immediately. If the warehouse uses a batch bar code system, the quantities from the scanner should be uploaded to the system immediately after the physical receiving is complete. Either way, the merchandise information is updated fast for everyone in the organization to see in real time. Manual entry of receiving sometime after the fact is less efficient and prone to error.

The system should inform the receiving crew if merchandise is for stock, floor display, or a special order. Stock inventory can be moved and scanned to any available rack location. Efficient warehouses with effective employees use locator systems that allow merchandise to be easily put away, easily found, and allows for the best use of space and time.

If the merchandise is not on display, your operating chain should include a function to identify items that should be moved to a showroom. Quick operations will have a designated floor transfer area in their warehouses.

A cross dock system can be put in place for special orders. Like the merchandise to display system, merchandise to be delivered can have a special area. Again, this can speed up the process of getting the merchandise in and out.

Any paperwork including bills of lading, packing lists, freight invoices, and receiving registers should be organized by the truckload and forwarded promptly to accounts payable.

Delivery Scheduling: Sales can be scheduled for delivery by one person or several people. Either way, customers should be contacted fast to set a date. The faster your customers are booked, the faster your revenue cycle. Other than the date and time of delivery, all relevant notes and COD requirements should be dealt with on scheduling. Cutoff product levels should be established by piece, cube, and/or stop. The goal is filling up trucks each day. Cutoff times also need to be in place so that the manager knows when to start pulling product.

Even small mom and pop operations benefit greatly from doing it this way as opposed to pulling a paper sale, writing a delivery, and sticking it on a clip board.

Delivery Picking and Preparation: At cutoff time, picking information is generated. In large operations with mechanical pickers, racks, and levels, it is best to pick by aisle as opposed to picking by customer. In this way the crew does not go back and forth, revisiting the same warehouse areas. In smaller, non-racked warehouses it may be faster to pick by the customer.

The cutoff time to start picking will depend on the average amount of preparation that is required to get the merchandise ready for delivery. This can be anywhere between a half day to two days.

Operations that spend more time on merchandise preparation are ones that have happier customers and fewer delivery-related service issues. Operations that deliver wood-made products in the box have more service issues than those that take the merchandise out of the box and deluxe it.

As mentioned above, all merchandise that comes in and out of a building needs a signature. Delivery receipts, therefore, need to be generated for the date of delivery. This can be done on paper or on a tablet/ iPad device that allows for a customer signature.

Deliveries should be routed using a mapping program. These programs allow for big savings in people hours, customer time, and driving costs. Once the route is mapped, the customer can be texted, called, or emailed with the delivery time window.

Finalizing Delivery: Customers sign for merchandise upon delivery. If they sign electronically, some advanced systems can auto-finalize the sale. For companies that use paper delivery receipts, these receipts and any money collected should be submitted to the office as soon as the truck returns at the end of the day. Either method works well.

Businesses that have a broken link here tend to have open sales that sit in their system for long periods of time. This leaves them exposed to theft, collection problems, and unpaid sales tax issues.

Accounts Payable: Each day, receiving information should arrive from the receiving manager. This should be filed into a “Merchandise received, waiting on invoice entry” file.

Each day, merchandise and freight invoices arrive from vendors. This should be filed into an “Invoice not entered, waiting on receiving” file.

Even if an invoice arrives before a shipment, it should only be entered when there is the verification of receiving the goods. At that time, the costs can be adjusted. Actual landed costs are reflected in the cost of goods. Without this link, costs, as well as product pricing and gross margins may become inaccurate.

On accounts payable entry, the receiving and invoices should be matched and then filed into an “Entered, to be paid” file.

Expense invoices follow a much simpler route. Just enter them when the mail is opened. Don’t let invoices stack up on someone’s desk without being entered. If this occurs, your debt situation would be understated. Then on the date when all the entry happens, you may be shocked by how much money you suddenly owe.

Check Writing Process: Check runs are often prepared weekly. Once per week, on Wednesday, for example, review an account payables open aging or cash requirements by due date report. Depending on your cash situation, decide on what you want, or don’t want to pay. Make your selections in your system. On Thursday, print and sign the checks. Staple the office check stub to the invoice. Put it in a paid by vendor file.

Ledger and Financial Statements: In an integrated enterprise system, all information from cash, accounts receivable, inventory, accounts payable, and payroll end up in the general ledger. Journal entries are made automatically to the proper account.

Do your bank reconciliation on line daily or a few times per week. This allows you to catch any additional charges that need to be entered. It also helps catch cash errors that occurred in accounts payable or bank deposits.

If your financial statements are set up properly in advance, you should be able to just push a button each month for your master business performance reports. You will automatically get:

- Profit and Loss Statements – this will show you sales, cost of goods, gross margin, operating costs, and net income for various profit centers.

- Balance Sheet – this will show you your general business health as far as what you own and what you owe.

- Cash Flow Statement – this will show you your cash position at the beginning of the period, why it changed, and the cash position at the end of the period.

There are many operational links that are critical for the health of your business. Strong functional links produce strong information. This efficient chain allows your employees to better serve your customers. Weak links destroy information. They make business difficult. Examine your operations chain and ask, “Does it make sense to do it this way?” “Are we doing it this way because we always have?” “Could there be a better way?”