Making a perfect delivery is best, but promptly resolving delivery problems can boost your competitive edge.

After seventeen years of helping furniture retailers improve the operations side of the business, I am much more sympathetic to doctors and lawyers who complain of being approached at social functions with medical or legal problems. Friends and acquaintances frequently want to discuss situations involving broken retail promises and delivery disasters. Occasionally they share an experience of a superb delivery. The most ironic was a recent complaint by a furniture retailer about a new appliance delivered to his home. His apparently minor problem had not been resolved for three months, despite numerous phone calls. What I wanted to say, and probably should have, was that his store had kept me waiting for two months with a similar problem.

Making a perfect delivery is best, but promptly resolving delivery problems is another way to boost competitive advantage and earn the next sale. Whether the problem is a manufacturer’s defect or a delivery error isn’t important. Your reputation is on the line! It is important that the process you put in place assures customer satisfaction every step of the way.

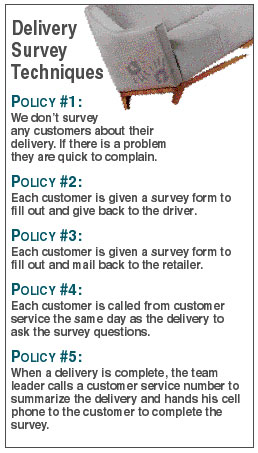

This article will describe several approaches (policies) used by retailers to handle delivery problems. Each of these will be examined so that you can craft a policy to help you find your place among the best of the best Benchmark Retailers.

It is surprising in today’s competitive environment that some retailers don’t use at least one of the survey techniques (Policies #2-#5 at left). Leaving the collection of this valuable information to chance is a mistake. Without good information, how can your managers identify and correct specific types of service failures? The fact is that some dissatisfied customers don’t bother to complain; they just take their next purchase elsewhere, and then tell friends and family about their unhappy experience.

Retailers who use Policy #2 will get their positive surveys returned, but delivery teams have been known to throw away unfavorable forms. Another difficulty with this policy is that consumers may be too timid to report negative experiences on forms that drivers can easily read.

Giving customers a survey form in a prepaid postage folder to mail back (Policy #3) generally yields a good cross section of responses. An added benefit is that customers are more likely to report negative experiences if the delivery team cannot see what they are writing. One innovative retailer asks customers to visit their web site, complete a survey form and insert their order number. Upon completing this task, the customer is rewarded with a discount coupon they can print out.

Some retailers call every customer the same day following a delivery and others call a sample selection (Policy #4). If a problem is reported, Benchmark Retailers have the ability to take appropriate action ranging from scheduling an immediate service call to providing an even exchange or an upgrade if the specific item isn’t in stock. Care should be taken to have these follow-up calls made by someone who has the authority to start corrective action. Having a telemarketer make impersonal data collection calls will not have the desired effect.

Policy #5 and a variation of this approach have achieved the highest success rate. When the delivery is complete, the delivery team leader calls the customer service number from his mobile telephone. He or she provides key information including any problems and then hands the phone to the customer. Survey questions are then answered, appointments are made if service is required, and customers are thanked for their order. A variation of this policy can be used as an addition to policies #3 or #4. Mail in cards or calls are used, to collect data, but if a delivery is less than perfect, the lead delivery person calls immediately from the customer’s home so immediate and appropriate action can be taken.

Bottom line, problem deliveries are a fact of life, but how your company reacts to resolve the issue can actually strengthen your customer relationships.

Tips to help make your deliveries perfect

SHIP COMPLETE: Make sure everything needed for the delivery is on the truck. That includes parts and equipment such as mirror brackets, shelf clips, assembly tools, polish and cloths. We have seen instances where 48 inch tables were delivered with 36 inch glass tops, beds delivered without bed rails and the list could go on and on.

DRIVER APPEARANCE: Surprising as it may seem, retailers who insist that all their delivery people be neat, clean and well dressed, recognize improvements in safety performance and customer satisfaction. Always put a full-length mirror by the warehouse door so the delivery staff can see how they look to customers

ENTRY/ EXIT PROTOCOL: Review your delivery team’s entry and exit procedures. Before entering a customer's home, they should always wipe their feet, put down runners when needed and avoid damaging walls. Some Benchmark retailers have booties to put over shoes to avoid soiling the carpets and floors. It is also important to make sure they complete a final wipe-down to remove handprints or dust from case goods and plump the pillows before leaving. It is an excellent idea to request that one of the previously mentioned surveys be used.

PICK THE RIGHT TRUCK: Always choose a truck whose size is appropriate for your customer's location. Sometimes it makes more sense to deliver in your service van than trying to navigate tight quarters with a large straight truck.

LONE DRIVER RULES: Drivers working by themselves must be encouraged to do their own planning and use their mirrors effectively. If necessary they should be instructed to get out of the truck and check clearances before maneuvering.

HELPER POLICY: If a helper is on the truck, it should be standard procedure for him to get out of the truck to guide the driver as he backs into a driveway or maneuvers between parked cars or trees. This will save time and reduce your expenditures for mailboxes, shrubs and lawn repair.

ASPHALT DRIVES: Instruct your drivers to beware of new asphalt driveways and even older asphalt ones on extremely hot days. A heavy truck can make ruts and the power steering can dig holes in pavement.

OVERHEAD CLEARANCE: Beware of overhead clearance restrictions such as tree limbs, wires, walkways, bridges and entrances to parking garages and docks. Those overhanging oak branches on Southern gated communities are tough on truck roofs. Decals on the front corners of the box that are visible in the rear view mirrors, make inexpensive and effective reminders. To bystanders the numbers are reversed but they show the truck height correctly in the rear view mirror. Most retailers have paid for needlessly smashed truck top fronts and damaged corners.

DRIVER QUALIFICATIONS: Drivers must be qualified for each truck size and weight they drive. Requirements range from a basic drivers license to a Commercial Drivers License (CDL) with options of straight truck, semi, doubles combinations, air brakes, hazardous materials and more. The weight brackets are: under 10,000 pounds; 10,000 to 26,000 pounds; and over 26,000 pounds. Driver qualifications are more stringent as weight and vehicle complexity go up.

NEW EQUIPMENT: Keep the above ideas in mind when buying a new truck. In particular, look for truck and box designs that are lower profile, are more maneuverable, have cabs that are easier to get in and out of and have good ergonomics. Whether you use a pullout ramp or a tailgate lift, many of these new designs make the box closer to the ground and easier to use. Don't forget to consider partially or non-opaque roofs that let light in and are more damage resistant than aluminum. Finally, put adequate interior restraints and padding to tie off products so they arrive in top-notch condition.

MEASURE & TRACK DELIVERY PERFORMANCE: You should have a chart updated daily that every delivery team can see showing their performance for the previous day and month to date. If they delivered 10 stops and one item on one order had a problem, the score is 90%. This is a tougher standard than calculating against the total number of items delivered. The sense of competition and modest incentives yield great results.

ROLE OF MANAGEMENT: Management bears responsibility for proper training and equipping of delivery teams. When there is a driving incident, the warehouse supervisor may want to blame it 100 per cent on the driver when information was available that could have prevented the problem. Nevertheless, the driver must pay attention at all times and use the helper.

Daniel Bolger of The Bolger Group helps companies achieve improved transportation, warehousing and logistics. Questions can be directed to Mr. Bolger care of FURNITURE WORLD at dbolger@furninfo.com.