View your retail operation through the “eyes” of process management, and your business will start moving toward realizing its full potential.

Reengineering efforts have companies in pursuit of the promise of dramatically improved quality, service, productivity and profitability. The most significant effect of this "reengineering revolution" is the focus on-and the resulting increased awareness of-business processes. The eighties saw a "Quality Revolution" in the United States and Europe. Companies spent many millions of dollars and effort-hours on Total Quality Management (TQM) and Continuous Improvement. As the nineties unfolded, reengineering came into vogue and again corporations continued to invest heavily. Still, through all this, relatively little attention has been paid to what could be thought of as the core basics: That process optimization is dependent not only on how a process is designed, but more so, on how it is managed.

The pursuit of process excellence is no different for a retailer than for a manufacturer or call centre business. There are basic similarities that exist across all business types. Process Management is one of these. Every organization is a collection of processes, both technical and social in nature. These processes are the typical business activities the company performs that produces value, satisfy customer needs and generate income. There should be no doubt that the management of a company's processes is the key to the organization's success. As is true in football, even the best playbook is worthless if execution is flawed.

Generally, retailers will look for improvements in stock turnover, sales revenue and value of ticket to name but a few. All these performance metrics are important but, fundamentally, if the basic process is flawed then anything following will be flawed as well. Once you view your business through the eyes of Process Management, real progress can be made toward improving the business and its efficiency.

David A. Garvin, professor at Harvard Business School reflected in a recent article, "When a company has fixed its processes through TQM or reengineering, it hopes to end up with superior processes. But those processes still have to be managed. How they are managed will determine whether the company realizes their full potential."

Successful process management requires continuous documentation, analysis and improvement efforts to streamline and redesign in order to remain competitive in a dynamic business environment. There are a number of highly sophisticated business modeling and simulation tools available to evaluate and manage an organization's processes, but they all must start with a thorough understanding of the basics: process inputs, transactions, outputs and the interrelationships of each. Once defined, we are able to:

- Understand how processes interact in the company's own "business system."

- Locate process flaws that are creating systemic problems.

- Determine which technical process failures are caused by social system failures.

- Evaluate which activities add value for customers.

- Streamline and improve workflows.

- Identify processes that need to be redesigned and/or areas that need to be restructured.

- Improve efficiency and customer satisfaction.

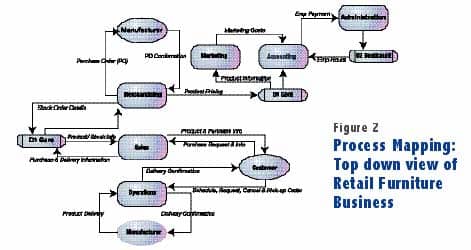

This approach applies to every aspect of a Furniture Retailer’s business, whether it is sales, merchandising, operations, visual display, accounts, or customer service. Each part of the business must be addressed logically. In this way the business owner or CEO can view the generic business process map and begin to identify where gaps exist.

Process Management

There are four steps to improved performance that can be identified so that companies can take action.

Scoping the situation: When a process fails to perform as required, we have a gap, a crisis, a fire. All these terms imply a sense of urgency. The tendency for most problem solvers is to look for the flame (gap) and to take whatever action is required to extinguish it. For this we are praised and rewarded; consequently, we have become extremely proficient fire fighters. Unfortunately, extinguishing the flame does not necessarily eliminate the flow of fuel that allowed the fire to erupt. Our quick fix solves the immediate crisis, but adds a "work around" or a "band-aid" to the process. These non-valued added steps close the gap, but leave the root cause intact. Band-aids with time and under stress tend to fall off, leaving the organization at risk. The fire returns and most likely it is when we can least afford it. To eliminate the fuel, there are four steps to improve the process:

System Mapping, Process Flow Charting, Gap Origin Definition and Gap Closure.

System Mapping: When output does not meet expectations, a gap exists. In a competitive world, a small gap in customer satisfaction can quickly turn into a large gap in market share. Rather than continued crisis managing, the alternative is to isolate the source of the fuel. System Mapping offers that possibility. As part of the first step in System Mapping we broaden our scope to encompass the entire business system - the combination of our process plus our suppliers’ that together provide our customers with desired outputs. When given a puzzle, most of us seek out the edges and corners to establish the boundaries before we look at the details. We then follow the typical problem solving flow:

- Identify existing and/or potential performance gaps.

- Determine their origin.

- Prioritize them by the potential risk or opportunity that they offer.

- Develop solutions that either minimize or eliminate the gaps.

- Implement the solutions.

- Verify successful gap closure.

Unfortunately, the "fire" tends to distract us. We zero in on the obvious effect, rather than backing up and looking at all the potential contributing causes. We try to guess the nature of the puzzle without even knowing the scope of analysis required. This tendency is the result of the fact that managers are rarely rewarded for watching the fire burn. Heroes are made by taking action - even if it is the wrong action. But leaping before we look will, at best, result in a waste of time and at worse, a temporary solution that contributes to future failures. Before we get into detailed process de-composition, we need to know where to drill. System Mapping provides the structure and discipline to look holistically before we dive into the details. System Mapping can encompass a corporate wide evaluation or focus on a single department or individual. The methods and intent are the same - create a clear understanding of why the system is behaving the way it is and what steps can be taken to optimize its performance. From here, we will focus on identifying the gap root cause. The source could be internal to the company (due to process design, execution or even organizational structure), caused by our suppliers, or even a combination of the two. A more detailed step-by-step analysis is required; process flow-charting is then the second step in Process Management.

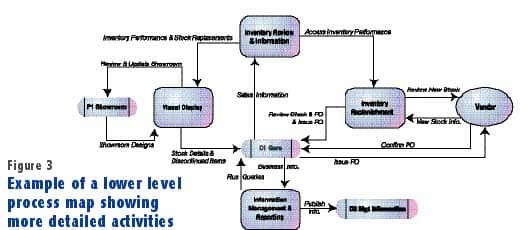

Process Flow Charting: Also called process mapping, the objective here is to clearly define how the process functions: who does what when. The environment in which managers operate their businesses is hardly stable and predictable. Processes vary within a company due to a variety of factors: different people with different skills operating under different managers with different suppliers. Variation in the inputs frequently yields variation in the output.

There are three types of processes:

- Core Process: The primary activity that produces the output that customers purchase.

- Technical Support Process: Includes the activities that influence the core process performance.

- Social Support Process: The activities that influence the workforce's performance.

Support process are just like the foundation of a building; they tend to operate behind the scenes. They literally support the core work that generates the product or service the customer is willing to pay for, but they are generally considered overhead, non-proprietary, are frequently neglected and often outsourced. Examples of support process include: accounting, human resources, information systems and maintenance. They are essential to the success of the organization, but the customer does not identify them or their outputs as part of their specifications. No matter how well designed and maintained the core process is, a poorly built and maintained support system will eventually collapse taking down the core process with it.

A thorough analysis and understanding of these process segments will help to determine an organization's stage or state. Specifically, these stages include:

- As Is: The actual process including all its inefficiencies and non-value-added steps.

- Should Be: The original design intent, a process absent of all non-value-added activities.

- Could Be: The theoretically possible, utilizing an "enabler" and yielding quantum improvement.

Gap Closure: The desired end-result of this process management activity involves achieving gap closure. Selecting a successful strategy to close the gaps is both a critical and difficult decision to make. At this point, the company's strategic options are either to continuously improve existing operations, thus taking the organization from the "As Is" to the "Should Be" process state; or redesign operations, radically altering the way work is done. This will move the company from the "Should Be" to the "Could Be" process state.

With these steps completed, the real question becomes, "Does this organization require incremental improvement (Continuous Improvement) or a quantum jump (Business Process Redesign/Restructuring) in performance?" Your customers and competition dictate the answer. Customers can be unreasonable and want the world, but if it is physically impossible, then your attempts to satisfy them will drive you out of business. If your competition is capable of satisfying this requirement then you have no choice.

Process Improvement Strategies & S-Curves

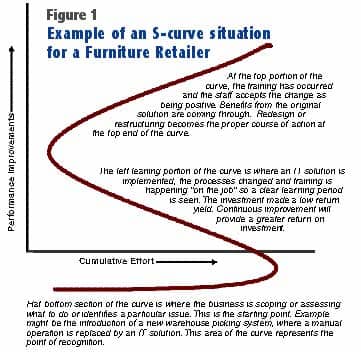

If the objective is to fully capitalize on available opportunities, it is necessary to take into account not just what is theoretically possible, but what is realistically feasible given the technological, resource, capital and cultural constraints present. In his book Innovation: The Attacker's Advantage, Richard Foster describes a technology "S-Curve," that reflects the benefit derived as compared to the effort exerted when undertaking process improvement initiatives. He suggests that, at least in part, the appropriate action to take is dependent on the organization's S-Curve position, as well as its operational and organizational constraints.

At the top of the curve, the benefit derived via continuous improvement is marginal as compared to the effort exerted. Because of the limited gain, redesign or restructuring becomes the proper course of action. However, redesigning a process is of limited value at the bottom of the curve. In this case, continuous improvement will provide a greater return on investment. Of course, the challenge is knowing when the company is at the top of its "S-Curve." Most successful companies undertake both continuous improvement and business process redesigning concurrently. This is because one never knows when the competition will innovate and leap to a totally new technology curve, thereby changing the measures by which customers gauge performance gaps.

Process Mapping: The Tools

Many people associate process mapping with basic flow-charting. There are many Retailers using this approach now mainly due to the ease of use and the fact that a “picture tells a 1000 words”! There are a number of tools and techniques available and each captures a different aspect of a given process. Proper tool selection depends on three factors:

•Audience: Who you’re trying to sell.

•Intent: Why you are documenting.

•Gap: What is it - a cost, quality, service or speed issue.

The areas of concern are, for example, reducing cycle time, eliminating flawed hand-off, optimizing resource utilization, determining activity-based costing, selecting optimal material positioning, creating easy-to-use problem-solving or decision-making procedures, and others. The tools and techniques are not all created equal and it is necessary to the audience and its skill level in order to develop the appropriate process flow. Six of the most useful tools available to help an organization map its processes are:

- Top Down Flowcharts

- Block Diagrams.

- Flow Process Charts.

- Work Flow Diagrams.

- Process Maps also called Cross Functional Flow Charts or Deployment Charts.

- State Change Charts.

Most documentation efforts still start out manually, especially when undertaken by a problem-solving team. Fortunately, a multitude of software packages are now available that improve the ease of document creation, updating, tracking, visualization and presentation.

Conclusion:

Effective process management requires a clear appreciation of what process or performance gaps exist on a broad systems-wide basis. A system map provides this perspective and is the first step completed as part of gap identification. Once identified, gaps are prioritized based on the risk posed or opportunity present. Gap origins are defined as part of process flow-charting or process mapping. Selecting the appropriate course of action to achieve gap closure is dependent on technical and social constraints.

An organization's process improvement potential is reflected by its technology S-Curve position. Depending on this position, redesigning technical processes may also require a focus on continuous improvement of social systems. The most successful organizations handle these projects simultaneously.

A variety of process mapping tools and techniques make it easy for process owners to visualize processes in their "As Is," "Should Be" or "Could Be" states. The challenge is knowing the audience objectives and skill sets in order to select the "best" tool for process visualization. Proper tool selection brings focus to critical process and performance gaps, minimizes project start up pitfalls and ultimately leads to successful gap closure. In this way, process mapping and - where necessary - business process redesign can help an organization realize its fullest potential.

Philip Pugh, an experienced consultant and Business Manager specializing in Process and Organizational improvement and is the Operations Director for Tribune US, Inc (TUS) a consulting company based in Washington DC. Tribune US, Inc. TUS is a subsidiary of Tribune Business Systems Ltd, a London based company. TUS offers a range of products and services to customers in the Retail, Financial Services, Insurance and Manufacturing sectors.Tribune US, Inc is a recognized specialist in the field of Process Management and Process efficiency with applications to assist in continuous improvement. If you have questions about this article contact Mr. Pugh at pugh@furninfo.com.