Most financial managers will agree that 30 to 36% per year is a realistic inventory carrying cost after consideration of basic inventory interest, warehousing costs, insurance, damages and obsolescence. For example, typical retailers can reduce NAS (Not Available for Sale) from 6% to under 2% of warehouse inventory. Best performing retailers will be under 1%. The key to NAS is timely evaluation and resolution, whether it be repair, return to vendor, send to clearance or scrap. GMROI calculation at the sku level will drive review of slow moving or obsolete inventory.

You should have goals for each of the categories and take action steps to restore categories that are out of balance. The size of your operation may determine whether you see this essential information daily or weekly. After all, Cash is King.

Perfect Deliveries

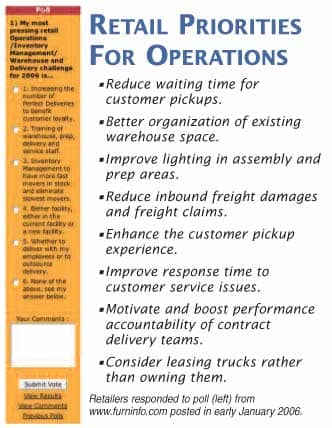

Achieving more perfect deliveries was chosen as the major goal by twenty-four percent of survey respondents. Perfect delivery measurement is the net result of improvements in every previous step in the process. A perfect delivery results only after you have selected the right product lines, the salesperson has realistically presented the product, the warehouse has properly handled and prepped the product and the delivery crew has executed all the steps required to ensure customer satisfaction.

In measuring perfect deliveries, you need to break out sub-categories that list reasons for each less than perfect delivery. The individual category measures should include service calls resulting from manufacturing defects, product damage due to the delivery itself, damages to your customer’s property, not-at-homes, sales errors, administrative errors and customer errors. These should be reported at the truck level and then summarized by week and month, typically in an Excel spreadsheet. Achieving 97% perfect deliveries for reasons under the control of your warehouse and delivery staff is an achievable goal. How do you compare with best performing retailers?

The benefits of improving perfect deliveries are substantial. Studies have shown that making an exchange or picking up an item for repair, costs an average of $250-$300, about five times the average original delivery cost. This cost includes setting up a service call, prepping another piece (assuming you have it in stock), delivering the replacement piece, picking up the original piece, inspection, disposition and administrative expenses. In many cases, an exchange or out of home repair consumes the entire sales margin and may even result in a loss.

Training

Sixteen percent of survey respondents noted that training is their highest priority for 2006. Best performing retailers develop outlines for each job function and actually train while others just pay lip service to training. If you are just organizing your training efforts, a good place to start is by writing detailed job descriptions. Some retailers have single page per function descriptions and others take the time to produce fifty page “soup to nuts” corporate manuals. Either can be successful if they are written in plain English and other languages understood by the workers. When you make your expectations clear, most workers will do their best to meet them. Training should also include information on the use of appropriate materials, work stations, tools, etc. If you find that you need additional organizational expertise in certain areas, consider bringing in outside talent to get your organization up to speed.

Facility Improvement

Improving an existing facility or moving to a new facility was noted by thirteen percent of responders. Accomplishing the improved inventory control mentioned earlier may free up sufficient space and should always be a first step taken before investing in capital improvements. Many existing facilities can be updated to meet retailers’ needs with improved lighting, reorganization of the space, more dock doors, customer pickup accommodations and racking. Fire protection requirements are serious issues that should be given extra attention when considering upgrades to existing facilities.

If you have plans to build a new facility, two key issues beyond the building itself to consider are access for customer pickups and maneuvering room for the 70 foot tractor trailer rigs delivering merchandise.

Computer tools are available to determine the storage space required for your mix of merchandise and future plans. You will need enough receiving and delivery doors, sufficient staging space, racks for cube utilization, a repair area, break room and administrative space. Trash and corrugated handling are significant opportunity areas for efficiency gains.

There have also been significant changes in building design to offset higher energy costs. Energy incentives up to $1.80 per square foot are available under the Energy Policy Act of 2005 for both new construction and renovation. Additional energy incentives may also be available from your local electric utility.

Delivery in CompanyTrucks or Outsource?

Only 9% of respondents said they will consider changing from their present method of delivery in 2006 as the top priority. Whether you deliver with your own trucks or use an outside delivery service, it is most important that you realize that your customers don’t really care who delivers your furniture. Their main goal is to receive a first class delivery free of hassles. Customers want delivery and placement at the promised time in a professional manner. From the customer comment cards and reports I see, many retailers are doing an excellent job. When things do go wrong, it can turn into a nightmare for the customer and your company.

Small retailers in many areas of the country, may not have the option of hiring a qualified home delivery service, but in metropolitan areas there are shared or dedicated delivery services that can provide home delivery services. Many retailers report that outsourcing the delivery function has freed them to concentrate on the business of retailing. Delivery companies are 100% devoted to delivery and the numerous duties associated with hiring and firing drivers, trucks, breakdowns, tolls, parking tickets and legal compliance.

In conclusion, operations success doesn’t just happen. It is the end result of knowing your objectives, making plans to achieve them and monitoring the plans for continuous improvement.

Dan Bolger helps furniture companies achieve improved transportation, warehousing and logistics. You can send inquiries on any aspect of transportation, warehousing or logistics issues to Dan at dbolger@furninfo.com.

See many of Dan Bolger’s articles posted to the article index archives on the furninfo.com website.