Once you decide to stop sending repairable furniture to clearance, you need to prepare your staff and managers to be fully engaged in the process.

Furniture Repair by Peter Schlosser

Why do we continuously shoot ourselves in the foot? How many times have you taken a trip somewhere with an infant, knowing that a favorite toy would easily placate her crying, only to leave it at home? Or consider my recent ride through the Arizona desert, where, upon running low on gasoline, I would think, I’ll wait until the next station to fill up. Thank heaven there was a next one. I guess the same could be said of retailers who hire a consultant and fail to plan for success.

The last article I wrote for FURNITURE WORLD Magazine generated a lot of response. Clearly, there are warehouse managers, customer service managers, COOs, CFOs, and owners who are sick to death—like me—of the ever-burgeoning pile of NAS goods in the warehouse. Anyone who has had to conduct a huge clearance sale knows the queasy feeling of watching goods leave the warehouse at pennies on the dollar…and the inevitable “good cheer” from the repair staff who says, “Man, we sure sold a lot of furniture today, didn’t we!” Yeah. They don’t realize that even though you may have sold it for cost, you really didn’t, because “cost” isn’t the exact amount you paid your supplier for an item. The actual cost also includes storage, handling, repair, insurance, lighting, leased space, et cetera. In truth, you lost your shirt.

YOU NEED HELP IF...

Now, with that in mind, remember back to your last clearance sale. Calculate the cost of goods sold, then subtract the amount of cash received from the sale. If this is a negative number, you need help.

If your customer service manager “therapeutically screams” in her car at lunch, you need help. If your warehouse manager spends more time on a lift truck with his head in the racks, rather than making sure that the best possible quality furniture is being loaded onto the trucks, you need help. And if your first-time successful delivery rate is below 90%, you really need help.

FAIL TO PREPARE? PREPARE TO FAIL

A repair consultant shouldn’t just fix your shop problems, train your repair staff, and leave. He should examine the problems driving the glut of damages. He should create a proactive plan that stems the tide of furniture being shoved into the repair area, not augment the shop in response to poor handling and inspection. Repair consulting should be a comprehensive plan involving the entire warehouse.

But again, we as humans routinely fail to plan for such a visit, thus the premise of this article: Shooting ourselves in the foot. Consultants are actually private tutors, in a way, bringing years of knowledge and experience right into your facility, for you alone to benefit, without interruption or outside interference. But sometimes, when I or my fellow consultants who work in operations, sales, finance or marketing arrive, management has decided that the “show must go on,” and that is just one way that things can go drastically awry.

Let’s consider three conditions that, if I knew they were present, would make me consider delaying or canceling a job simply because I know my final results will be less than stellar. They are:

The beat goes on. The people who should be concentrating solely on their training—repair staff, drivers, deluxers—are working their normal everyday routines.

We have everything already. Despite encouragement, management has not followed up with pre-visit requests to completely and accurately inventory the shop tools and materials, or provides no feedback whatsoever. Therefore, the skills that need to be transmitted, may not be supported by the materials and tools needed for the lesson.

Who are you again? During a visit, management is non-existent, hostile to any suggestions, or continuously interrupts the training to solve minor issues.

First, think back to when you were in algebra class. Your teacher was in front of the room teaching x and y. Now, imagine if, simultaneously, you were writing an essay that was due next period. What sort of math did you learn that day? None.

Impossible. If staff cannot be sequestered for training, how can they possibly learn anything new? The result will likely be failure.

Getting back to preparation. Before existing repair operations can be evaluated, management must provide inventory data to help assess the repair staff’s skill level at a glance. For example, suppliers such as Touch-Up Solutions make toners that are dye-based (transparent) and pigment-based (opaque). There are uses for both. But inexperienced shops usually have more of the pigmented toners on hand because they can be used to make faster cover-ups. The problem is that pigmented toners also block out grain. Repairs that have the grain obscured look muddy and amateurish. Thus, if too many pigmented toners are used, then the staff will almost certainly need help with spot repairs. Or, if the staff has never heard of glaze, then they haven’t tried faux finishing, and virtually all imported furniture is in some way or another faux finished.

Finally, it is critically important that management take an active role in learning repair, or at least the basic concepts of repair, so they are better informed when faced with a less-than-cooperative repair person. Further, management should not look at the consulting experience as a hindrance to their operation, or a disruption of the flow process. The more your staff learns, the more you can relax.

Some retailers do manage to get the most out of their investments in consulting. What follows are the experiences of three FURNITURE WORLD Magazine subscribers who were well prepared, and set themselves up to get excellent results.

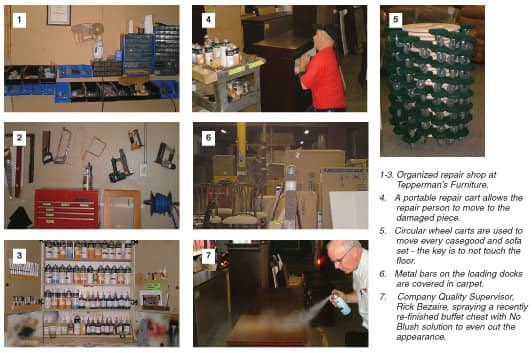

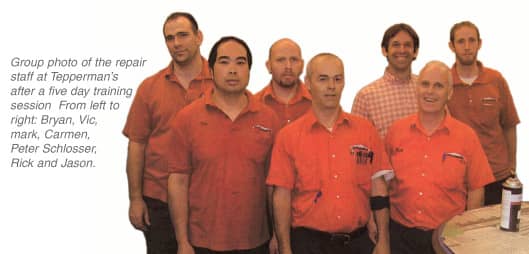

Tepperman’s Furniture

Andrew Tepperman and his family carefully planned their repair consulting visit. Before the formal training started, management and consultant spent time at their Windsor and London, Ontario facilities taking notes and making recommendations for improvement. Once written recommendations were submitted, the company formulated a plan for improvement that involved a repair staff “master finisher” position for future in-house training, and nailed down the areas that they felt made them most susceptible to building damaged inventory.

Management then ordered materials, purchased tools interviewed their staff, and carefully planned to get the most out of on-site training. While training, the work routine was halted while the staff learned new, or better, ways of making furniture repairs. Andrew cleared his work schedule to watch and learn so that he could better manage the process and act as a coach later on. Other members of management were briefed daily about progress, and were encouraged to ask questions. Post-visit, the company took some time to think about incorporating what was learned into future growth, and set quality improvement goals. In the following weeks, their first-time delivery rate was in the nineties.

Sylvan’s Furniture

Karen Shaul of Sylvan’s Furniture, Lewiston, ID, actually shut down her warehouse for a week of training. There were no deliveries. This idea proved to be very rewarding for the company. Sylvan’s warehouse staff consisted of four guys who doubled as delivery drivers, openers, inspectors, showroom helpers, you name it. None really focused on repair, nor did they have any touch-up experience to speak of. Using repair materials they had ordered in advance, the team went through the showroom, fixing problems on all of the showroom samples. The showroom environment closely approximated their customer’s homes: Close quarters, people watching, trying to cause minimal contamination of the air. After this basic training, a repair department was outfitted and more advanced repair techniques were demonstrated.

Thomas Home Furnishings

Thomas’s had recently redesigned their Douglas, AZ warehouse when their energetic and optimistic operations manager Tim Wilson realized he wanted to have more control over inventory. As Ashley dealers often discover, they had experienced explosive growth, but damages were mounting as well. Their warehouse consultant, arranged for a repair consultant to bring a full set of repair materials into Thomas Home Furnishings’ warehouse. When it was time for training, the shop team had their work routines put on hold for the week. Dozens of clearance and NAS pieces were pulled to serve as training examples. The team was taught how to triage a piece, deciding if it was worthwhile to repair (opting against orphaned rails and the like). The remaining furniture items were then distributed among the group. Repair methods were suggested, and proper techniques were demonstrated as necessary. Members of the team were given one-on-one guidance if they had difficulty with certain techniques such as a burn-in or faux finishing. Often this kind of personal attention helps to bring along a repair tech with exceptional abilities (see the article in the April/May issue of FURNITURE WORLD on hiring and training repair people posted to www.furninfo.com). And in this case Thomas Home Furnishings was lucky enough to find that they already had a person with amazing artistic talents.

TAKE CONTROL OF INVENTORY

If you plan in advance of a consultation, you will find that the overall results are much better than if the entire process is ad hoc. People simply cannot learn if they are distracted. Techniques can’t be demonstrated if proper materials aren’t on hand. Furniture repair is a precise and conceptual art, requiring a mastery of color, technique and style which must be learned over time.

The whole point of hiring a repair consultant is to take control of your inventory. There are very few owners who don’t have damaged inventory problems, or who haven’t had to organize a clearance sale to make room for new goods. Take a moment and think about what is filling up your racks! Is it good stock? Is it current? Or is it a bunch of even-exchanged pieces with minor problems that your staff can’t fix because they either don’t have the knowledge and experience, or don’t have the materials and tools they need, or both? Parts may be free, and replacements might solve the problem, but the cost, and believe me there is a cost, of a dissatisfied customer who must wait weeks for her problems to be solved, are immeasurable. Good thing, too, because if you think your clearance sale was bad, lost business is a silent killer.