In this installment of Furniture World Magazine’s Better Bedding and Mattress Sales series, we expand upon information presented in “Bedding Anatomy 101”, published in the July/August 2012 issue.

In that issue we identified appropriate situations for sales associates to introduce information on mattress specifications into their presentations, and described some of the best ways to talk about mattress technologies. If you missed the last issue, or any of the previous seven installments in this widely read series, please visit www.furninfo.com/ series/ bedding.

MATTRESS COMPONENTS

It’s no secret that our mattresses are full of unseen components such as fabric ticking, flame retardant barriers, fiber layers, foam layers, and springs.

Bedding expert and frequent Furniture World contributor Peter A. Marino, explains it this way. “Sleep sets are loaded with components and features such as coil count, gauge, tempered steel, memory foam, edge support, steel spans in the boxspring, pillow tops, modular and coiled boxsprings, and on and on. You can dump every one of those features on your customers and even bring them up as abstract benefits, but those abstract benefits won’t do a thing for your customers until they are presented as relevant features and relevant benefits.” He also told Furniture World that, “Whenever I begin the training of new salespeople who’ve never sold bedding before, I ask them to take a good hard look at the sleepsets on the sales floor. Then I say these words: ‘Memorize the way these mattresses appear to you right now, because that’s the way every one of your customers will see them when they walk in here for the first time.’

Dr. Marino’ statement points to several important ideas that will be the focus of this and future articles.

- In order to present relevant benefits, sales associates must, in addition to discovering a customer’s relevant needs (a topic we discussed in detail in the last issue), also have a working knowledge of mattress components.

- Even though many customers find information on the Internet or in other stores about mattress components, when they walk into your store, they may only have a vague conception of how these bedding “nuts and bolts” affect the three important attributes of comfort, support and durability.

- Sales associates are well served to have a clear strategy for thinking and talking about how bedding manufacturers incorporate components into mattress systems to provide the attributes mentioned in the preceeding paragraph.

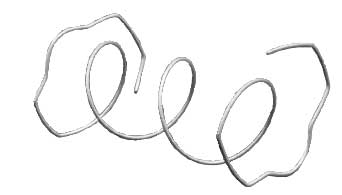

This coil unit pictured below is composed of specialized open offset coils known as LFK coils. LFK coils are described as cylindrical, columnar or barrel shaped. Note the unknotted coil ends and squared off tops and bottoms. Photo supplied by Leggett & Platt (coil trade name Lura Flex).

MATTRESS SUPPORT

So how might sales associates think about components? Bob Muenkel, Director of Sales Education & Development at Serta International, suggests that they start by considering comfort and support as the ingredients of a good night’s sleep. He says, “Once sales associates understand the role of comfort and support in producing a good night’s sleep, they can look at the ingredients in any mattress regardless of brand and figure out what’s a comfort material and what’s a support material.

“For example, the whole function of support,” Muenkel continues, “whether it’s an inner-spring system, a displacement system like air, or a foam system such as latex or urethane, is to maintain proper spinal alignment, so your customers’ muscles can relax and be restored throughout the night. Whatever the supportive system that they are on, it needs to contour to them, not them to it. It also needs to offer the right amount of positive resistance, and to be intelligently designed so it can sense weight or pressure, and gently respond with equal and opposite pressure in order to maintain the middle. Comfort layers need to provide pressure relief so the sleeper can fall asleep quickly and reduce excessive tossing and turning, comfort and support are necessary elements for a good night’s sleep and there are multiple ways of getting there.”

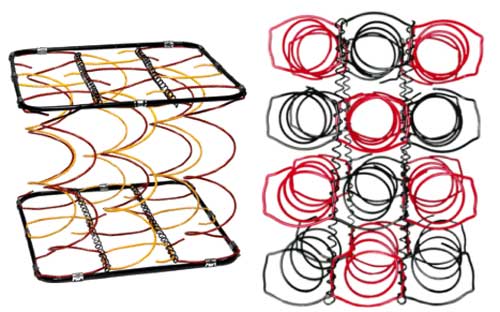

Pictured (above left) from Hickory Springs Bedding Products is a coil unit with alternating right and left facing open offset coils (trade name ProACT). Coils are attached to each other with long spiral helicals and clipped to a border wire.

Pictured (above left) from Hickory Springs Bedding Products is a coil unit with alternating right and left facing open offset coils (trade name ProACT). Coils are attached to each other with long spiral helicals and clipped to a border wire.

Pictured (right) is a Hickory Springs LFK coil (trade name InnerACT) unit composed of alternating right and left hand facing coils, a configuration that increases stability. The open offset LFK coils are cylindrically shaped.

Dr. Michael Breus, creator of the Dr. Breus Bed® produced by Comfort Solutions as licensee, further comments on the role of proper mattress support. “Support creates spinal alignment,” he says. “This allows muscles to relax, permitting a healing process to occur during sleep. We rely completely on our sleep systems to provide good posture. A proper pillow and mattress facilitate spinal disc rehydration and the secretion of growth hormone to help heal tissues and muscles that have been damaged throughout the day. Support materials should be flexible. Since bodies are supposed to move during sleep, it’s important that the combination of materials and layers in a bed conform and give support, as well as move with the sleeper.

“Support components are critical to good posture while sleeping. Think about it,” he concludes. “There is no one telling us to ‘sit up straight’ while we are sleeping so, we rely completely on this passive system for support.”

INNERSPRING COILS

The primary mattress components that provide support are springs, polyurethane and latex foams. We will look at each of these in this and coming issues of Furniture World, beginning with springs.

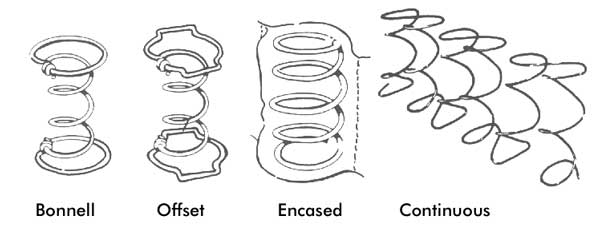

Traditionally, innerspring coils have been incorporated into mattress systems as a primary supportive component. They are often organized into four major coil system types: the Bonnell coil, offset coil, individual pocketed, and continuous coil. Before getting into the benefits of each type, it’s useful to note that not all coil systems are created equal. Even when comparing mattresses having the same coil type, units may differ in the amount of metal used, the density of the coils, the gauge (thickness of the wire), height of the coils and the number of wire turns in each coil. These differences translate into variations in support characteristics and durability.

Given this complexity, it’s tough or impossible for sales associates to explain the exact effects of these variations in engineering. Even so, it is possible to make a number of general statements about the coil types used in bedding construction. Fortunately, this kind of information is generally more than enough for most customers.

Pictured are fabric encased coils. Within this type of construction, the tops of the coils can move freely since the tops are not bound by helicals. The image supplied by Leggett and Platt shows that pressure applied to an area does not perturb the surrounding coils.

COIL COUNTS

We will start with a discussion of coil count, industry and consumer buzzwords. And, as was noted in the last installment in this series, it is something that consumers often ask about in an attempt to establish the relative value of two or more innerspring mattresses.

We asked Mark Quinn at component manufacturer Leggett & Platt to comment on the relevance of using coil counts to establish value during the sales process. He explained that, “Sales associates have to take care when comparing the coil counts of different mattresses. If the gauge of wire and the construction of the coils in two different mattresses are equal, then a higher coil count translates into more surface coverage and better support characteristics for the core. If, however,” he says, “there are differences in the construction and materials in the coil, then it gets a lot more complicated.

“This creates a challenge for retail salespeople who are trying to compare mattresses that each have, for example, 500 coils but use different gauge wire, or have coils of different heights, or different kinds of coils. It becomes hard to make generalizations. RSAs need to be careful not to confuse the consumer. That’s why we created Geek U (sleep-geek.com), a free supplemental education platform available to anyone and everyone in the industry. There are 7 levels to Geek U, and we try to educate RSAs on the right way to approach consumers about this sort of topic.”

Quinn gives Furniture World Magazine’s readers a general observation about the correlations between coil count and price.

The unknotted variation of an offset coil known as an open end offset provides better spring action. Note the hourglass shape of the coil. Photo of coil (trade name Verticoil), supplied by Leggett & Platt.

The unknotted variation of an offset coil known as an open end offset provides better spring action. Note the hourglass shape of the coil. Photo of coil (trade name Verticoil), supplied by Leggett & Platt.

“Promotional mattresses,” he says, “are usually in the 200 to 300 coil count range. Mattresses in the 400 to 600 coil count range are typically in the more premium categories.”

The counts can go much higher, W. Brent Limer, National Product Manager, Hickory Springs Bedding Products, explains. “An ultra high-end mattress might be closer to the 800 coil count level. But coil-on-coil constructions that put sheets of micro coils above the supporting springs can add to the total coil count of the bed.”

Again, coil count is only an indicator of the quality of a coil spring mattress. It is possible for a mattress with a higher coil count to be less durable and of lower quality than a similar mattress with a lower count. For example, the higher count mattress might use inferior steel, a different kind of coil or be less well designed. It might also have springs with fewer “working turns”. Each turn of a coil is defined as a 180 degree loop of the spring.

Serta’s Bob Muenkel elaborates. “The number of turns in the wire can change the durability of the spring,” he tells us. “Springs have to have memory. What is memory? If you take a six-inch spring, and compress it a thousand times, then measure its height again and it is now only five-inches, well, it didn’t maintain its memory too well. Memory can be a function of the gauge of the wire, the number of turns within that six-inches and, the tempering of the wire as well. Generally, the more turns within a given space, the more durable, longer lasting and softer the coil will be. And finally, tempering wire strengthens it, locks in the memory of its original shape, and helps it to bounce back to that original shape longer.”

“Regarding coil count,” Hickory Spring’s Brent Limer explains, “in addition to the raw count, a number of other specs go into making coils.

“I work on the technical side of the mattress business. Looking at coil count from that perspective only, I believe that coil count doesn’t matter. But, consumers do want to know the coil count, so RSAs need to know this information as well. In addition, they should know what type of coil units are in their mattresses, as well as the features and benefits of those units. However, telling customers about the details of the wire’s gauge and number of turns will most likely confuse them.”

Our experts generally acknowledge that springs maintain their support characteristics much longer than, for example, polyurethane foam. And, everything else being equal, the more metal in an innerspring mattress, the more durable it will be. Ways to incorporate more metal into a mattress are by adding higher coil counts, taller springs, more coil turns and thicker, stronger wire. Changing any of these factors also affects mattress firmness, so getting to the right mix of mattress support characteristics and durability is a complex engineering task.

The Bonnell coil has an hourglass shape, knotted ends with a round top and bottom. The knotted end offset coil differs from the Bonnell by having a squared off top and bottom. Individually wrapped (encased) coils are barrel shaped or cylindrical in shape. Each coil is enclosed in a separate, flexible fabric pocket. Continuous coils are created from a single pice of wire.

COIL COUNT VS. COIL DENSITY

Counting coils seems like a fairly straightforward calculation of multiplying the number of coils in the width of a mattress by the number of coils in its length.

“There are a lot of people who don’t understand coil count,” explains Serta’s Bob Muenkel. “If there’s no foam encasement, sales associates are quoting coil count. If there is a foam encasement, they use the term coil count, but are actually quoting coil density.”

Muenkel invites us to look at coil count, usually quoted for a queen sized mattress, verses coil density. “The terms are technically different,” he explains. “So, let’s use the example of an inner-spring unit. We will pretend that we are looking at an innerspring unit that head-to-toe has 25 coils in each row, and 20 rows. The coils go right to the edge of this mattress that contains 500 coils.

“But let’s say the manufacturer decides to surround the innerspring unit with a foam encasement. They can’t put foam rails around the entire perimeter of the 500 coil unit in our example and have it remain queen size. So, they take one row of coils, head-to-foot off the left and the right sides, and one coil off of each of the rows at the head and the foot.

“Instead of 20 rows of coils, the mattress now has 18, and instead of 25 coils in each row, there are 23. The mattress now has 414 coils, but the industry still says the coil count is 500. That’s because the density of coils, the closeness of the coils, and the performance of the coils in the entire middle of the bed will be the same as a the original queen sized 500 coil bed in our example.”

COIL TYPES

As was mentioned previously, bedding manufacturers use different coil types in their mattresses, categorized as Bonnell coils, offset coils, individual pocketed coils, and continuous coils.

In his book, “The Golden Rules of Selling Bedding”, published by Furniture World, Dr. Peter Marino tells of an experience he had while working as a sales associate. “Related to what we have just stated,” he writes, “is an experience I had at a bedding factory designed to increase one’s product knowledge and selling skills. The instructor had lined up six sets along side of each other, each set in an identical color and cover, each mattress on an identical boxspring, each mattress identically thick, each one put together to feel conformingly plush, but each one with a different coil count ranging from a 312 to a 660. We were asked to get on each mattress to determine each one’s coil count. All of us were pretty well stumped. The instructors assured us that other salespeople before us had been just as stumped as we were.”

Marino’s point is well taken. When testing out mattresses for one to five minutes in the store, customers can have a tough time, discerning differences in coil count, coil type, wire guage used, steel quality, etc. Can they tell if a certain coil hinges 10 per cent better? If another is less likely to make noise? If this one with knotted ends feels more stable? Probably not. That doesn’t mean, however, that coil specifications do not have a big effect on the experience customers have once they get their new mattresses home. Specs do matter. And, that is why, when appropriate, sales associates can use this information to help customers make better purchase decisions.

BONNELL COILS

Bonnell is an open coil design with an hourglass shape. The diameter of each coil is largest at the top and bottom, tapering toward the center. The tops and the bottoms of Bonnell coils have the defining characteristic of being round. Each wire end terminates with a knot that enhances stability.

Bonnell coil design makes it generally affordable. This type is often seen in mattresses in the 300 to 400 coil count range.

Hickory Springs’ Brent Limer told us, “The Bonnell innerspring is one of the oldest technologies we produce and still accounts for the majority of innersprings sold, though some of the market for this coil has been replaced by promotional open-end offset units.

“Compared to open-end offset units,” he continues, “Bonnell coils are typically heavier gauge coils that use more steel. Because they are knotted, they offer a little more stability, producing a good support surface. When the spring is compressed and rides down, the round coil meets a flat helical wire, making it a bit more firm.”

OFFSET COILS

Offset coils are similar to Bonnell Coils. Regular offset coils have an hourglass shape, but instead of being round at the top and bottom, they are squared off. This allows adjacent springs to fit together like a hinge when the coils are placed in rows.

Offset Coils come in both open ended and knotted varieties. The knotted version uses more steel and is more stable. The unknotted variation called an open end offset offers better spring action.

“The open-end offset coil,” Hickory Springs’ Brent Limer observes, “doesn’t have knots that can cause the unit to hold up when it starts to spring. It is flat or almost flat where it’s laced with the helical wire, producing a more gentle ride and a softer feel.”

Another subcategory of Offset coil is the LFK. It is an offset design with coils described as cylindrical, columnar or barrel shaped. The open unknotted ends provide more elasticity than the typical offset coil, giving firm support, and improved stability.

LFK Coils are often seen in beds with coil counts starting around 500 and going up to the 700 coil count range.

“With an LFK,” Limer continues, “you get a greater hinging effect, resulting in an even more gentle ride.”

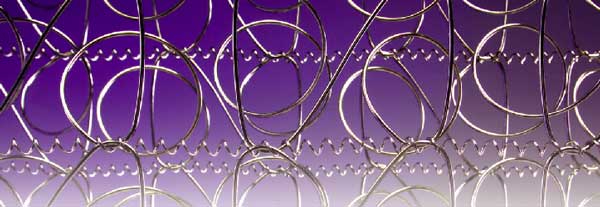

Continuously woven wires running the entire length of a mattress are joined by helicals in the above photo of a continuous coil unit supplied by Leggett and Platt.

Continuously woven wires running the entire length of a mattress are joined by helicals in the above photo of a continuous coil unit supplied by Leggett and Platt.

COIL ARRANGEMENTS

Individual Bonnell and Offset Coils can be bonded, interlocked, clipped or welded together. They may be oriented head-to-foot or side-to-side. Some constructions use alternating right and left turned coils, a method that reduces motion in adjacent springs.

These spring types are usually held in rows with long spirals called helicals of lighter (higher) gauge wire that also bind adjacent rows of coils. These helicals are said to lace (tie) the individual coils together, allowing for flexible independent spring action while maintaining a uniform surface. The perimeter of spring units are defined by a heavy border rod clipped to the outermost coil spring edges as well as the ends of the helicals. This rod serves to stabilize the unit and ensure firm edges.

CONTINUOUS WIRE

Continuous coil configurations are formed by a row of coils made from a single piece of wire. This design allows for innerspring units with higher coil counts, made of thinner gauge wire, using less steel with fewer turns per coil.

“Continuous wire units.” says Serta’s Bob Muenkel, “are also called multi-elastic units.” To visualize how these units are made, he suggests that we, “Imagine a wire that starts at the head of the bed, comes up, forming a coil, then goes down forming a coil, then comes up and it’s never interrupted. The orientation can run side-to-side or head-to-toe, and there are benefits to either variation depending upon what characteristics the manufacturer is trying to achieve.”

Continuous coil mattresses are generally durable and affordable. A drawback is that this construction method may allow for more transfer of motion.

FABRIC ENCASED COILS

Individually wrapped coils are barrel shaped or cylindrical in shape. Each coil is enclosed in a separate, flexible fabric pocket. The design allows for coils to compress more independently, resulting in less motion transfer.

“Pocketed coils are welded together with a sonic weld toward the middle of the pocket so the coil tops are able to move freely,” says Leggett & Platt’s Mark Quinn. “There is typically a lot of comfort built into the these coils, more so than a unit that is helically tied. You could lay right on top of a pocket coil unit and be pretty comfortable without putting any foam on top of it at all.”

“The coil pockets,” adds Serta’s Bob Muenkel, “can also be glued together into rows or spun in rows that are then glued together. There are variations, but generally, wrapped coils have a tendency to be found at premium price points. Continuous wire units overlap from premium to the lower-end of the premium. Open coils can be found at any price point, but the vast majority of promotional bedding contains open coils.”

COILS USED AS A COMFORT LAYER

The overall quality and durability of an innerspring mattress depends on more than just its supporting springs. Other elements such as cushioning materials that are placed on top of spring units have a huge effect.

“When manufacturers pile a huge amount of foam and cushioning layers on top of the springs,” Hickory Spring’s Brent Limer observes, “at some point springs just become a layer that supports those materials.”

But foam and fibers are not the only materials that can be used as comfort layers above spring units. Recent advances in coil spring technology have spawned small coils that can be used in place of foam close to the sleeping surface of the bed.

Mark Quinn of Leggett & Platt explains. “Our tests show that polyurethane foam used on top of spring units in the majority of beds made today,” he says, “lose about 40 percent of their firmness over time and Visco loses about 18 percent. This reduces the comfort life of the bed.

With innersprings you don’t get that effect. If you look at firmness loss over a hundred thousand regulator cycles, the two and a half inch coils we call Softech only lose, about four percent of their firmness. Our 2.5" Softech coils were designed to sit right on top of the mattress and be the comfort and the support of the sleep system.”

Hickory Spring’s Brent Limer elaborates, saying, “There are coil-on-coil constructions that put sheets of micro coils above the supporting springs. This adds to the total coil count of the bed. Our micro coils add 1,000 or 2,000 coils to a queen-sized mattress. And, it is important to note,” he told Furniture World, “that these micro coils provide comfort as well as support. And because they are made of steel, the coils are less likely to break down as rapidly as other mattress layers, decreasing the potential for body impressions to form.”

HYBRID MATTRESSES

Before moving on to explain other types of bedding support materials, let’s take a brief look at the role of coil springs in hybrid bedding.

Leggett & Platt has been promoting the hybrid bedding concept through its campaign that explains the benefits of adding springs into specialty foam bedding products.

“Leggett & Platt’s research at Kansas State University,” elaborates Mark Quinn, “has shown that innersprings sleep 28 percent cooler than other surfaces. There is a lot of discussion out there about visco foam sleeping hot, so this is important. I’m not saying visco foam is bad, I’m just saying it is not conducive to a cool sleep environment. It’s a real issue for consumers which is why you are seeing all of the visco/gel products in the market. And, according to the recent Barons article (http://yhoo.it/QcSeij) there are many people who find that having sex on a Visco foam bed is more difficult.”

Quinn told us that adding springs back into a foam mattress produces a hybrid that can alleviate these issues, “Plus,” he says, “We’re promoting the concept that hybrid equals springs and in our case, fabric encased springs, plus any kind of specialty layer like a gel or visco or latex. And the great thing about a hybrid is that a consumer can get into the specialty category in what we call the Ultimate Hybrid, and get added benefits.”

“Specialty sleep started out as a solid foam bed with Tempurpedic,” adds Brent Limer. “Then, industry momentum moved toward pocketed coils. The next step is to mix the two, utilizing what has made specialty so successful. That is the future of hybrid construction.”

Next Issue

The next issue in this bedding series will examine the different kinds of foams and their roles as supportive and comfort layer materials.

Furniture World is the oldest, continuously published trade publication in the United States. It is published for the benefit of furniture retail executives. Print circulation of 20,000 is directed primarily to furniture retailers in the US and Canada. In 1970, the magazine established and endowed the Bernice Bienenstock Furniture Library (www.furniturelibrary.com) in High Point, NC, now a public foundation containing more than 5,000 books on furniture and design dating from 1620. For more information contact editor@furninfo.com.