This installment of Furniture World Magazine’s Better Bedding and Mattress Sales series will expand upon information presented in the last three issues on mattress construction. In the July/August installment we looked at how retail sales associates can successfully introduce information on mattress specifications and technologies into their presentations. The ups and downs of innersprings were presented in the October/November issue and in December/January Furniture World looked at Conventional, HR and Memory Foam. If you missed these or any of the previous nine articles in this widely read series, please visit www.furnin fo.com/ series/ bedding.

Conforming & Cooling Gel

“The latest and greatest thing in memory foam these days is to add gel to it,” says Allen Platek, Vice President Marketing at Sealy. “Almost every bedding manufacturer has a gel memory foam offering.”

Gel, often tinted with an identifying green or blue pigment can be incorporated into mattresses in various ways.

“A gel foam,” explains PFA’s Bob Luedeka Executive Director of the Polyurethane Foam Association, Inc. (PFA), “is a foam with additives in it to provide extra features. All kinds of things can go into these beads for different purposes so it’s a way to get really creative with foam.”

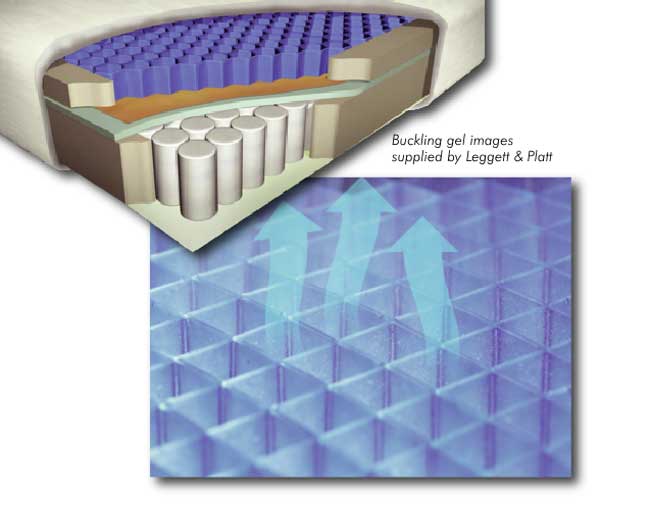

Gel can be swirled into or dispersed as flecks or beads into foam. It can also be incorporated into mattresses as a solid layer, or molded into honeycomb, waffle or other shapes, sometimes called buckling wall gel.

Adding gel to foam gel boosts density measured in pounds per cubic foot and can increase the level of support or IFD, a measure of how much the foam is pushing back at certain depths as it is compressed. A more complete discussion of IFD and density can be found in the “Bedding Anatomy 103” article that ran in the January/ February 2013 issue of Furniture World. It can be found online at

www.furninfo.com/series/bedding.

“Gel can be described as an amorphous or semi-solid material.” notes Bob Steelman, VP Sales and Marketing (Corporate Bedding) for Carpenter Co., a manufacturer of polyurethane foam and polyester fiber with manufacturing plants in North America and Europe.

“Originally gel was very expensive, heavy and difficult to work with. It was sold by weight and only used in ultra-premium mattresses. A layer of gel an eighth of an inch thick could add over 100 pounds to a mattress. That changed when Serta came out with the iComfort mattress line with gel infused into the foam. That innovation made the use of gel much more economical, and marketable. The introduction of gel into foam really resonated with consumers because of the way companies like Dr. Scholl’s had marketed the comfort and support of gel in shoe soles and other products.“

“Gel is found in bicycle seats, in workout gloves, and in the insoles of shoes,” adds Serta’s Bob Muenkel. “Infusing gel into memory foam creates a more supportive memory foam combination. So, that’s benefit number one. Benefit number two, depending upon the actual chemistry of the gel, is that it can also hold the sleeping temperature of the mattress down.”

As was noted in part 9 of this Better Bedding and Mattress series, one of memory (viscoelastic) foam’s defining characteristics is its ability to conform to a sleeper when exposed to body heat. Many consumers find that visco also has the unwanted side effect of concentrating body heat.

Foam chemists can influence the heat conserving properties of visco foams by changing formulations to create variations in foam structure and air flow. Generally, open cell formulations promote air flow and will sleep cooler than closed cell formulations, but adding gel to memory foam has been found to be an excellent way to disperse heat.

“Gel-infused memory foam has really just brought memory foam technology into the 21st Century,” remarks Bob Muenkel, Director of Sales Education & Development at Serta International. “By adding an extra support element to it, and also by adding at least to some degree, a cooler sleeping surface. Memory foam is insulating, much like a styrofoam cup. Gel is the opposite. It actually draws the heat away. So, when gel is infused into memory foam, there is a dual benefit.”

“In order to provide a cooling effect, gel must come in fairly close contact with the sleeper. Carpenter’s Steelman explains. “Specialty beds don’t have a quilted, covering layer. Instead, sleepers lay right on top of gel particles underneath the ticking, so heat transfers through that ticking pretty readily. In addition to gel, manufacturers may introduce additional phase change materials into foam that work toward getting the body to an optimum temperature and holding it there, rather than getting too hot or too cold. The sleeper feels an initial coolness and then the phase change material holds them at an optimum comfort level as far as temperature goes.”

To improve the delivery of gel’s benefits, manufacturers have recently developed new ways to introduce gel into mattresses.

“Recently,” Bob Steelman says, “manufacturers have figured out ways to better deliver gel over the foam. I believe that’s the next phase, but it is more expensive to put a solid gel layer on top of the foam, so it’s going to be limited to premium products.

“Gel can be skim coated on top of foam, but one drawback is that it is solid gel, and doesn't breathe. We actually punch holes in our skim coat to let the air circulate through. Other companies are working to patent processes that affect the cell structure of the foam so it can absorb the gel into the top layer without closing off foam cells. The benefit is that gel remains close to the surface and close to the body.”

Another way to get gel near the surface of the mattress is to introduce it as a comfort layer above a foam or innerspring core.

Cody Messner, Product Manager Bedding Group, Leggett & Platt told Furniture World that if, “Buckling wall gel forms the top layer directly under the ticking, it becomes a comfort layer, that’s soft to the touch.

“It’s a pure gel product, that’s not incorporated into foam as flakes or particles of gel. It’s anywhere from three quarters of an inch up to two and a quarter inches thick, depending on the desired characteristics. The gel is molded into columns of interlocking honeycomb or diamond shapes. Each honeycomb is an individual column. When pressure is applied, these gel walls buckle, reducing the pressure and dispersing it across the sleeping surface. In our product, sixteen to twenty-two percent of the contact surface is gel. The rest is open-air ventilation.

“The benefits of this type of product that retailers can talk about are pressure relief, back support, durability, and ventilation properties that contribute to a more temperature neutral sleeping surface. And, buckling gel can be used with any type of foam core or innerspring unit.”

Leggett & Platt’s Mark Quinn, adds, “This type of gel can be used to create something we call a hybrid, A hybrid as we define it is the addition of our Comfort Core springs which are fabric encased coils, with any gel, latex or memory foam topper. The gel layer is most often placed right under the ticking so that the sleeper can feel it. The gel buckles in, conforming to the body. Alternatively, the gel layer may also be placed under a thin layer of memory foam, latex or other bedding material.”

About Latex

According to Kurt Ling, CEO, Pure LatexBLISS, latex is technically not a foam, although this distinction is lost on many consumers, retailers and bedding manufacturers.

Whether the experts interviewed for this article referred to latex as a foam or not, there was complete agreement regarding the positive properties latex brings to a mattress.

“Latex is most widely known to be very bouncy,” observes Serta’s Bob Muenkel, “also extremely durable; it lasts a long time. It has a very lively feeling, almost the opposite of memory foam. And it’s been around longer than memory foam so it has a long, long track record. Plus, it has a tendency to sleep neutral when it comes to body temperature. It’s very breathable. And, what’s interesting about latex foam is that it gives push back support whereas memory foam conforms. Latex is an active support system, while memory foam is a passive support system. That’s not to say one is better than the other, they’re just very different feels.”

“In Europe,” adds Sealy’s Allen Platek, “latex is a huge part of the bedding market, but in the United States for some reason it hasn’t taken off. In the 1950s and ‘60s it was very big and, over time it ebbed. I am a fan of latex, but I think the disservice that’s been done to it is that no one has been able to do a good job of defining what a latex bed is. I’ve seen, manufacturers produce what they call a latex bed that contains only a half-inch of latex. This causes a lot of confusion at retail when the so called latex bed with a half inch of latex sells for $799, and another one that happens to have 12 inches of latex sells for $3,299.”

Latex Types

The two basic types of latex are Talalay and Dunlop.

Kurt Ling, CEO of Pure LatexBLISS tells Furniture World readers, “Talalay Latex, is more expensive and is more consistent in feel from top to bottom. It is also more breathable, more durable and comes in a wider range of feels. Dunlop Latex is less expensive and is poured in a mold similar to the way a waffle is made. Dunlop is poured more like a pancake. Dunlop makes a good core in a latex bed. Talalay can either be used as a core or in upholstery layers.”

“All Natural or 100% Natural Latex,” he says, “is more expensive, although blended latex; natural plus synthetic lasts longer.

Ling told Furniture World that Latex is rubber, not foam. You would not use foam to make a bumper, or soles on tennis shoes or a request ball. The properties of these two specialty sleep components are near opposites. The cell structure of the two are very different, the end benefit of feel is very different, and the performance life is very different.

Latex Attributes

We asked Hickory Spring’s Brent Limer if the density or ILD is a useful measure for thinking about latex. “Latex is only sold on ILD as far as the firmness goes, he observed. It starts at about 14 and goes up into the 30s.”

“ILD is the appropriate measure,” agrees LatexBLISS’ Kurt Ling. “That said, the number of inches of latex in the mattress is the key number to focus on when determining value of a latex bed or durability, or ability to relax muscles and relieve tension. Higher ILD numbers represent denser latex appropriate for support cores whereas lower ILDs represent latex appropriate for Upholstery layers.

“Most consumers do not ask about ILD,” he adds. “The numbers are meaningless to them. They want to know more about the overall feel of the bed not the specifics of each layer. They do ask about the number of inches of latex in the mattress. Consumers also ask if the latex is manufactured in the US or imported from Asia.

“As a support core, latex is a very durable and long lasting component. As upholstery, latex allows the consumers body to be lifted, be buoyant and provide a floating effect that helps relax muscles and relieves tension.”

What Buyers & RSA’s Need To Know About Latex

Furniture World asked Ling the main things retail buyers need to know about the latex mattresses they sell. “The major things they should know” he replied, “are if it’s an all latex bed or a bed with latex in it. The easiest way to tell the difference is look at the law tag. Also, know how many inches of latex are in the mattress, if the latex was manufactured in the US or Imported from Asia, if the support core Talalay or Dunlop, if the latex used in the upholstery is Talalay or Dunlop, and if there is foam or fiber on top of the Latex layers in the bed that minimize the feel or performance of the latex.

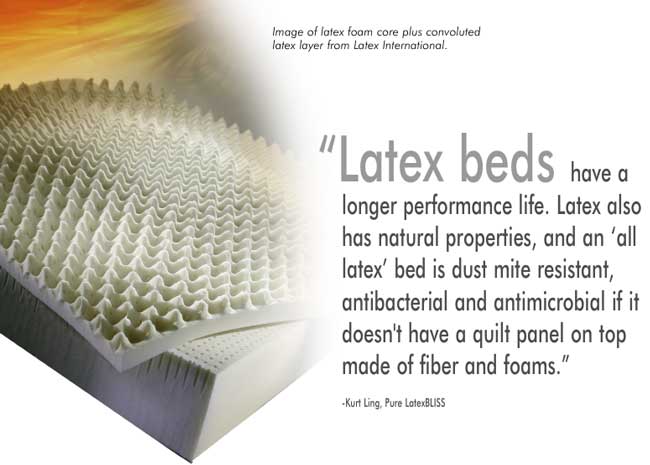

“The main things retail sales associates should know about latex,” he continues are, “first, the benefit for the consumer of sleeping on an all latex bed. Second, that latex beds have a longer performance life. Latex also has natural properties, and an ‘all latex’ bed is dust mite resistant, antibacterial and antimicrobial if it doesn't have a quilt panel on top made of fiber and foams.

Asked about how retail associates might identify customers who appreciate the feel of latex, he explained, “The easiest way to identify a latex customer is to find consumers who think they want a memory foam mattress but then discover that they don't like the feel of memory foam. Latex provides a lifting effect that is the opposite of the memory foam sinking effect. If the consumer doesn't like one, they are very likely to like the other. Consumers sleep ‘on’ latex whereas they sleep ‘in’ memory foam.

“Occasionally consumers will bring up latex allergies when looking for a mattress. With regard to latex allergies,” he notes, “you have to come into contact with it to have a reaction. In case your customer is planning on taking their mattress apart and touching the latex, even with a latex allergy, they can sleep on it without a problem. There are multiple layers of materials between them and the latex in their mattress including sheets, mattress protector, a cover and an FR layer.

“Also, the mistake many people make is only pitching latex's natural story. Although more natural than many mattresses, the number of consumers seeking natural mattresses is limited compared to the number seeking the feel of latex or want a latex rubber that will last a long time.”

Finally we asked him where he sees the market for Latex going.

“Specialty bedding is growing rapidly,” he replied, “Just ten years ago it was a very small part of the market. More than one of two consumers say their next bed will not contain springs. There are two options and both are experiencing rapid growth; memory foam and latex. The two compliment each other perfectly.”

Russell Bienenstock is Editor-in-Chief of Furniture World Magazine, founded 1870. Comments can be directed to him at editor@furninfo.com.