Dressing in the armor of digital tools is only as effective as a retailer’s

ability and willingness to do its due diligence in other important areas

that affect customer delivery satisfaction.

I recently read an article published on the Furniture World website entitled

“New Research Shows Impact of Delivery Experience on Major Furniture

Retailers.” I was pleased to see that something I’ve been passionate about

my entire career—perfect deliveries—was once again in the headlines. I agree

with everything cited in the article by Deliveright, a logistics and

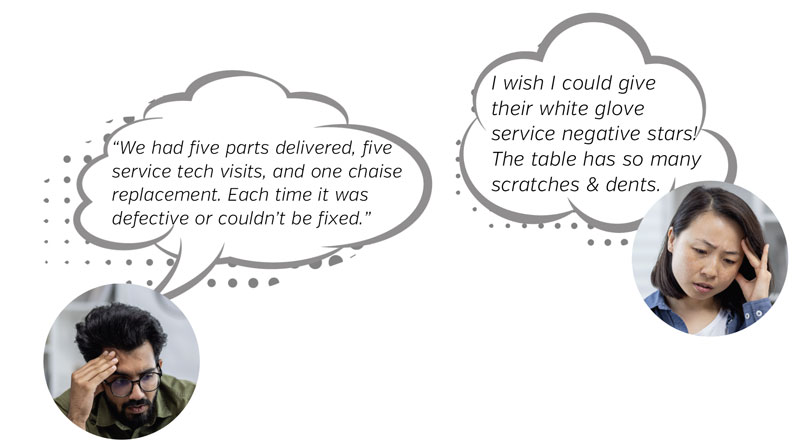

delivery platform, which noted that “26% of all reviews mention the delivery

experience, and 75% of those reviews mentioning delivery are negative.” The

article explained how digital tools could help “improve the final mile

delivery experience through better communication with the customer.”

There’s no debate that customers want flawless deliveries. Who wouldn’t? But

many other factors go into crafting a perfect delivery that cannot be solved

by relying on a single approach.

The Thin Balloon Margin Trap

I’ve written before about customer expectations in Furniture World, and I

must say that customer demands for delivery are higher than ever before, in

spite of the fact that a large majority of customers do not want to pay for

it. Before everyone piles on and says, “Hey buddy, it’s a fact of business;

you need to deal with it.” I’d like to reply, “Hey, it’s time to focus on

core issues affecting delivery satisfaction.”

Metaphorically, I see furniture retailing as a long, thin balloon that

represents an entire operation. Some owners squeeze the balloon in different

places, solving one issue while moving others to one side or another.

Ultimately, customers want great prices, excellent delivery, and high

quality. But when retailers drop prices, margins shrink and cost cutting

follows. Salaries are the easiest (and sometimes the only) expense that can

be controlled. Delivery quality suffers when people get laid off, or those

with questionable qualifications are hired to replace more experienced

workers at lower salaries.

Rolling Delivery Dice

It’s true that communication with customers is critical for making efficient

deliveries, but dressing in the armor of digital tools is only as effective

as a retailer’s ability and willingness to do its due diligence in other

important areas that affect customer delivery satisfaction.

My grandfather, Bill McCloskey, also a furniture operations consultant, used

to say to his clients, “Do It Right The First Time.” This seems simple,

right? But many retailers undo that logic and roll the dice when addressing

the 75% of negative customer reviews that mention delivery. Here are some

problem areas and remedies to consider:

-

Shipping in the box. Nope, I’m never going to agree

with this! Some retailers cut open the box’s top and front face, check

for common damages, and retape. This catches top corner and drawer

damage, but after thirty years of inspecting and repairing furniture, I

can guarantee that many other problems will be missed if you do this.

These include back panel, drawer and door operation issues, rear corner

damage, and construction flaws, to name a few. And once you cut open the

top and front of the box, your drivers now operate in a trash truck

rather than a clean, neat delivery vehicle. Manufacturers have gotten

exponentially better about putting near-perfect products in the box,

whatever their definition of near-perfect may be. But remember that when

the product gets to the inspection area of your warehouse, it is

well-traveled.

-

Draping pads rather than wrapping with tape. You may be

thinking that when tape is used, sticky pads get returned with tape all

over them! Drivers hate that. My question is: Who runs the warehouse?

Who is the manager? Buildings cannot be run based on the individual

wants and desires of employees. Efficient operations are run with

processes that work. Yes, draping is faster and very tempting,

especially if the load is light or can be put onto the truck so that

exposed panels and components run a low risk of damage. However, the

integrity of the initial loadout usually becomes compromised after the

first delivery. Protected surfaces get exposed. Forgetting to tie down

the load is potentially catastrophic. Furniture gets moved around as in

Tetris to get the load tight again for strapping. This can make

furniture that is simply draped with pads vulnerable.

-

Poor lighting in the warehouse and on trucks. If your

people can’t see what they are working on, they will miss a lot. No, a

flashlight isn’t the same as color-corrected LED troffers in the

inspection lanes. One of the most ingenious solutions I’ve seen was

designed by Jeff Winter at Furniture Mall of Kansas, which bathed

furniture with bright light from above and all around. Furniture is fed

into this inspection booth and only exits when it is perfect or marked

for additional attention. Process, process, process!

-

Inexperienced inspectors, deluxers, and technicians. I

am keenly aware that people with my skill set are rapidly disappearing

from the retail furniture store workforce. Furniture repair is similar

to other high-demand skills, like plumbing or welding. Repair

technicians spend years learning the trade and must adapt to unusual and

challenging repair situations. What happens if a repair tech is tasked

with repairing an Ashley B650 piece but has never fixed silvery gold

before? Likely, they will be told, “Figure it out; we load in three

hours.” I was overjoyed to discover that Mohawk Finishing makes this

color in a can, but I knew where to look and who to ask. There are many

instances where a driver with good repair sense is thrust into the

technician position but isn’t given enough training and ends up back on

a truck.

There are several ways to avoid this situation. Ashley Corporate has a

training center, Mohawk offers classes, community colleges provide art

classes, and industry consultants like me can visit and offer one-on-one

training.

Conclusion

When the furniture is sent out in excellent condition, the likelihood of a

perfect delivery rises exponentially. Coupled with powerful, intuitive

online communication tools, your hard-won, hopefully loyal, very vocal

customers will get the treatment they deserve. And you will earn respect

and, perhaps, adulation. It’s a win-win for everyone.